The Health and Safety Executive (HSE) is making waves in the manufacturing industry with a renewed focus on metalworking fluid management.

This is no surprise, considering the potential health hazards associated with these fluids – from skin irritation to respiratory problems.

Recent inspections have revealed a worrying trend: many businesses fail to meet the necessary monitoring requirements and the Control of Substances Hazardous to Health (COSHH) Regulations 2002.

What’s at Stake?

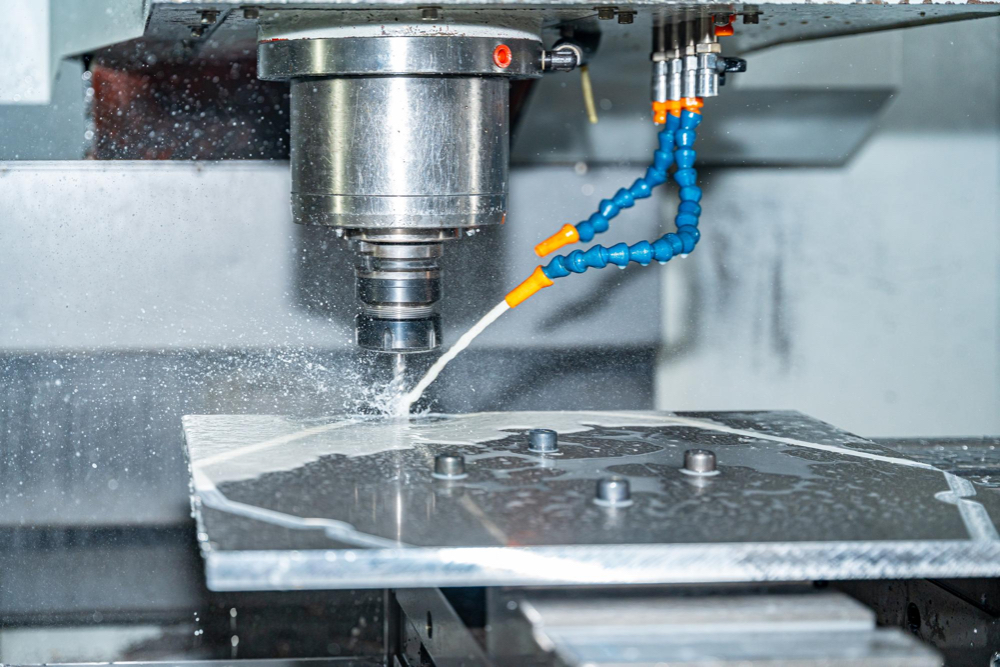

Metalworking fluids, often called “white water,” are essential for cooling and lubricating machinery.

However, exposure to these fluids – particularly through inhalation or skin contact – can severely affect workers’ health.

The HSE’s inspections are designed to ensure that companies have adequate control measures in place, such as:

Local Exhaust Ventilation (LEV): Systems that capture and remove fumes at the source.

Regular Fluid Quality Checks: To prevent bacterial growth and maintain fluid effectiveness.

Health Surveillance: Regular check-ups for workers exposed to metalworking fluids.

Failure to comply with these regulations puts employees at risk and can lead to costly fines and legal action.

A Growing Need for Fluid Monitoring

The good news is that more and more companies are recognising the importance of fluid monitoring.

We’ve launched fluid monitoring programs for over 30 new customers in the last six months. This highlights a growing awareness of the issue and a proactive approach to worker safety.

But how many companies still need to catch up?

While increasing interest in fluid monitoring is encouraging, the HSE’s findings suggest that many businesses still need compliance advice and help, raising concerns about the overall safety of workers in the manufacturing sector.

Don’t Wait for an Inspection – Take Action Now

If you’re using metalworking fluids in your operations, it’s crucial to review your safety practices and ensure you’re meeting all regulatory requirements.

Don’t wait for an HSE inspection to uncover potential problems.

Here’s what you can do:

Assess Your Current Practices: Review your control measures, fluid quality checks, and health surveillance procedures.

Seek Expert Guidance: If you need clarification on compliance, consult an occupational health and safety specialist.

Implement a Fluid Monitoring Program: Regular monitoring can help you identify and address potential issues before they escalate. Our team at Fluidsolve can help with this.

Protecting your workers is not just a legal obligation – it’s an ethical responsibility.

By prioritising metalworking fluid safety, you safeguard your employees’ health and well-being while also ensuring the long-term success of your business.

check out our other services here to find out more.